Rental products for the extraction and trasportation of tube bundles

- Aerial tube bundles extractor “push puller”

- Truck mounted mobile tube bundles puller

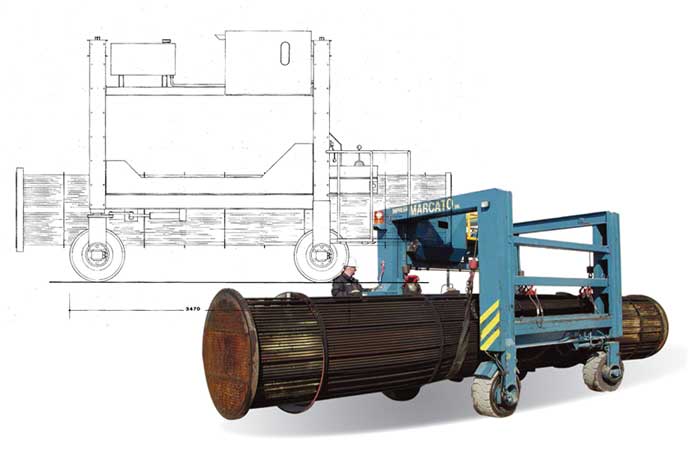

- Heat exchangers tube bundle transporter, straddle carrier “GORILLA”

Once the Bundle Extractor has placed the bundle on the ground it is the transporter’s turn that, completely substituting the traditional crane truck with trailer, picks the bundle up, transports it and then places it in the washing area where our Robots start washing it immediately.

Once the bundle has been cleaned with our robots, the transporter picks up the clean bundle and after it has taken it to the plant, deposits it on the extractor that then puts it back in place in the shell.

GENERAL DESCRIPTION

Our first bundle transporter was designed and built in the 80’s revolutionizing technology in the handling of the tube bundles. Now, we consider ourselves the leaders in the market for quality construction and durability in extremely demanding applications.

The tube bundle carrier conceptually derives directly from the gantry crane for handling containers in storage parks, or transport systems for concrete prefabricated items. It is equipped with a diesel engine coupled to a hydraulic pump which, by means of a control unit with tank, drives the lifting, steering and traction systems, allowing a remarkable simplicity of operating and smoothness of movement without the need for gearboxes, friction, mechanical transmissions, etc.

Technical data – Measurements:

- Weight capacity of bundle transportet: 20.000 Kg

- Translation speed: 25 km/h

- Wheels: No. 4

- Sterring wheels: No. 2

- Driving wheels: 4 always in engagement, with synchronization function ofthe revolutions in case of loss of grip of a single wheel

- Max. sterring angle: 45°

- Max. slope exceeded: 10°

- Lenght: 3.900 mm

- Height: 3.150 mm

- max. width: 2485 mm

- Weight of the machine: 4.500 Kg

- Max. tube sheet diameter: 1.650 mm

- Lifting speed: m/min: 1,00

- Engine: KOHLER

- Power: 29 Kw

SUPPORTING FRAME

The structure consists of a frame made of UNP and HEA series steel beams, complete

with tubulars and connecting plates, joined by welding and high strength bolts.

DRIVING

The driving is a four-wheel drive by means of oil-hydraulic servomotors incorporated in

the hubs: depending on the load conditions and the ground, it is possible to choose to

synchronize the rotation of the four driving wheels, thus creating a state of “locked

differential” movement; in this second case, the advancement is only possible with slow

speed, the selection is made by means of a button that is protected against accidental

or unwanted use.

An additional lever selector allows you to choose the speed.

The setting of the hydraulic oil circuit allows the differential rotation of the wheels if

the button above is not pressed.

Negative disc brakes with automatic operation are mounted on two wheels to guarantee

emergency braking and the parking brake.

Pressure releasing valves provide safety against overloads.

The braking effect on the moving vehicle is implemented with the speed lever which

acts on the hydraulic transmission system and is therefore progressive and powerful, as

well as safe.

LOAD LIFTING

The lifting is carried out by means of a suitable hydraulic cylinder which simultaneously

drives the four steel ropes at whose ends there are the hooks with a fastening device for

securing the slinging means; mass is also fixed at the cable ends for the correct

movement of the unloaded ropes.

The ropes are guided by a system of grooved drums and pulleys, the whole path is

protected by a guard, or is located inside the supporting frame.

- ease of use

- thirty years experience

- thousands of operations assets

- ous technological improvements

We are the only ones who design, build and even use own machines, this allows us to test our equipment continuously

- elimination of the 4-wheel steering for best constructive resistanceand and rediction of time maneuver

- elimination of the cushioning system on wheels for increased lifting speed and elimination possibility of breakage

- guidance system retractable type “stand up” for total control of the machine and maximum ease of access

We were the first…

Anno1985, from our idea the first bundle transporter, designed and built in our workshop

TYPES OF INTERVENTIONS

- Truck mounted budle extractor

- Heat exchanger tube bundle extractor

- Bundle extractor

- Aerial tube bundle extractor

- Extraction and transport of heat exchangers tube bundles

- Bundle extractor rental

- Heat Exchanger bundle push puller